- Home

- Product

- About

- Production

- OEM &ODM Solutions

- News

- Contact

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. Both are CE and RoHS certified, meeting European market certification requirements.

It meets different voltage and frequency requirements depending on the customer's country: 220~240V/50~60Hz; 110V/60Hz.

It includes a thermostat and temperature limiter to ensure customer safety.

Temperature range: 50-200 degrees Celsius.

Carton packaging.

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

DZL-062B

DZL-062B

DZL-062B

DZL-062B

DZL-062B

DZL-062B

DZL-062B

DZL-062B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-102B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-132B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-152B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-172B

DZL-082B

DZL-082B

DZL-20B

DZL-20B

DZL-20B

DZL-20B

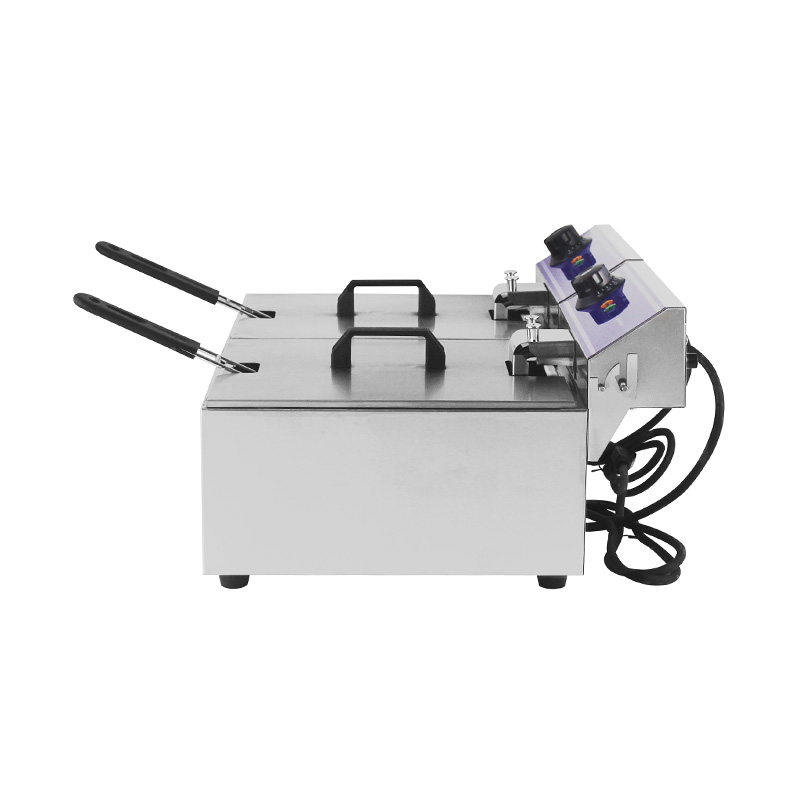

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. The fryer is CE, RoHS, and LFGB certified, meeting European market certification requirements.

It meets different voltage and frequency requirements depending on the customer's country: 220~240V/50~60Hz; 110V/60Hz.

It includes a thermostat and temperature limiter to ensure customer safety.

Designs include single/double cylinder, blue panel. Temperature range is 50-200 degrees Celsius.

Carton packaging.

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-10B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-061B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-101B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-131B

DZL-151B

DZL-151B

DZL-151B

DZL-151B

DZL-151B

DZL-151B

DZL-151B

DZL-151B

0_0004_IMG_5368

0_0004_IMG_5368

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-171B

DZL-081B

DZL-081B

This countertop electric fryer features a 201 stainless steel body and a nickel-plated iron frying basket, ensuring a robust and durable structure suitable for various small catering settings. The valveless design simplifies operation and enhances safety; the front-mounted blue function panel improves visual visibility and makes controls more intuitive.

The fryer incorporates a built-in thermostat and temperature limiter, allowing for precise temperature adjustment within the 50–200°C range, ensuring stable heating and effective user safety. Depending on the market, it is available with either 220–240V/50–60Hz or 110V/60Hz voltage configurations.

The product comes with a standard frying basket suitable for everyday frying needs. The entire unit has passed key certifications such as CE, RoHS, and LFGB, fully complying with European market safety and food contact standards. It is shipped in a cardboard box for easy transportation and storage.

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. It has CE, RoHS, and LFGB certifications, meeting the certification requirements of the European market.

It meets different voltage and frequency requirements according to the customer's country: 220~240V/50~60Hz; 110V/60Hz. Some can meet 380~400V/50Hz. Single basket configuration includes:

Equipped with a thermostat, temperature limiter, and valve to ensure customer safety.

Temperature range: 50-200 degrees Celsius.

Carton packaging.

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. It has CE, RoHS, and LFGB certifications, meeting the certification requirements of the European market.

It meets different voltage and frequency requirements according to the customer's country: 220~240V/50~60Hz; 110V/60Hz. Some can meet 380~400V/50Hz. It features a double-basket configuration.

Equipped with a thermostat, temperature limiter, and valve to ensure customer safety.

Temperature range: 50-200 degrees Celsius.

Carton packaging.

The product is constructed from 201 stainless steel, with the basket material being nickel-plated iron.

Voltage and frequency specifications are tailored to customer country requirements: 220–240V/50–60Hz; 110V/60Hz.

Features include a thermostat, temperature limiter, and timer.

Temperature range: 50–200°C.

Packaged in cardboard boxes.

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. RoHS certified, meeting European market certification requirements.

It meets different voltage and frequency requirements depending on the customer's country: 220~240V/50~60Hz; 110V/60Hz.

It includes a thermostat, temperature limiter, and timer.

The temperature range is 50-200 degrees Celsius.

It is packaged in a cardboard box.

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. It has CE and RoHS certifications, meeting European market certification requirements. Capacities are 20L and 30L wide frying baskets.

It meets different voltage and frequency requirements depending on the customer's country: 220~240V/50~60Hz; 110V/60Hz.

It includes a thermostat and temperature limiter to ensure customer safety.

Temperature range: 50-200 degrees Celsius.

Carton packaging.

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. Commercial capacities are 52L and 76L.

Both products are CE, RoHS, and LFGB certified, meeting European market requirements.

Different voltage and frequency requirements are met depending on the customer's country: 220~240V/50~60Hz; 110V/60Hz; 380~400V/50Hz.

Equipped with a thermostat and temperature limiter to ensure customer safety.

Temperature range: 50-200 degrees Celsius.

Wooden crate packaging.

The product is made of 201 stainless steel, and the basket is made of nickel-plated iron. The machine is designed with a door.

It has CE and RoHS certifications, meeting the certification requirements of the European market.

It meets different voltage and frequency requirements according to the customer's country: 220~240V/50~60Hz; 110V/60Hz. Some can meet 380~400V/50Hz.

It is equipped with a thermostat, temperature limiter, and power switch to ensure customer safety.

The temperature range is 50-200 degrees Celsius.

Wooden crate packaging.

The BC series is made of 201 stainless steel, while the E series is made of 430 stainless steel.

Depending on the customer's country of origin, it meets different voltage and frequency requirements: 220~240V/50~60Hz; 110V/60Hz. BC type can be 380V/50Hz

The BC series includes a thermostat, temperature limiter, and timer, while the E series features a computer-programmable interface for enhanced intelligence and customer safety.

Temperature range: 50-200 degrees Celsius.

Vertical fryers are packaged in wooden crates.

Ruian Weixinli Food Machinery Co., Ltd was established in year 1996. The company possesses advanced production equipment, strong technical capabilities, strict quality inspection procedures, and a scientific management system.

Our company always insists on being customer-centric and prioritizing quality belief. We specialize in manufacturing high-quality catering equipment and have developed into an international commercial kitchen equipment manufacturer, with main products including fryers, griddles, pluckers, crepe makers, etc., primarily for export to more than fifty countries and regions, including Germany, Italy, France, Australia, America and Southeast Asia.

Weixinli will continue to work hard, breaking through obstacles in the intense waves of competition, and carefully bringing customers top-quality products with excellent cost performance. We eagerly look forward to joining hands with you to create brilliance together.

Take step and get in touch with us today.

An Electric Fryer is a kitchen appliance designed to cook food by immersing it in hot oil heated through electricity. Unlike gas fryers, electric fryers use heating elements placed directly in the oil basin to deliver stable and controllable heat. This design allows operators to set precise temperatures, which improves consistency and helps maintain food texture and color during cooking. Electric fryers are widely used in commercial kitchens, restaurants, food trucks, and catering operations because they reduce the need for a gas line and simplify installation.

Electric fryers come in several configurations, including countertop units, floor models, and countertop induction fryers that heat more quickly and efficiently. They are favored where installation simplicity and temperature control are priorities. Temperature range typically falls between 150°C to 200°C, allowing a broad range of frying applications from French fries and chicken wings to tempura and doughnuts. Cleaning and maintenance are also more straightforward with electric units, as many include removable baskets and easily accessible oil drains.

When choosing an Electric Fryer for a busy kitchen, safety is a frequent concern. Operators should consider features like built‑in temperature limiters, overheating protection, and sturdy construction. Because oil reaches high temperatures, it's essential to select a unit with reliable insulation and a well‑designed lid or splash guard to reduce the risk of burns and fires.

Routine maintenance helps keep electric fryers running safely. Daily tasks include filtering and replacing the oil to prevent stale debris from catching fire. It’s also important to check electrical connections and ensure users are trained in safe operation. Clear signage and standard operating procedures further reduce risks associated with hot oil handling.

Commercial Electric Deep Fryers are often evaluated based on their energy usage and impact on operating costs. Electricity costs can vary widely by region, and using a fryer with efficient heating elements and well‑insulated basins can help reduce energy consumption. Many modern commercial electric fryers include programmable controls that reduce idle energy usage and adjust power according to cooking load.

Compared with gas models, commercial electric deep fryers can deliver consistent heat without the need for ventilation hoods in some jurisdictions, depending on local codes. This can lower initial installation costs and ongoing utility expenses. Additionally, precise temperature control contributes to consistent cook times, which also helps reduce oil absorption and prolongs oil life, lowering total operating costs.

Maintaining Commercial Electric Deep Fryers is vital for food quality, safety, and equipment lifespan. Daily cleaning should begin only after the oil has cooled to a safe temperature. Operators should drain oil through built‑in drains or external valves into approved containers. After oil removal, the interior surfaces should be wiped and washed to remove food particles and grease.

Weekly or monthly deep cleaning might involve removing heating elements, baskets, and filters, and soaking them in sanitizing solutions. It’s also useful to inspect gaskets, seals, and electrical components for wear. A regular schedule not only improves hygiene and performance but also prevents breakdowns that can interrupt service.

For Commercial Deep Fryers, temperature control directly affects food quality. Frying at too low a temperature results in greasy, undercooked food, while too high a temperature can burn the exterior before the interior is done. Commercial kitchens aim for consistent results to satisfy customers and reduce waste.

Professional fryers include thermoreats and, in many cases, digital displays that show real‑time oil temperature. Some models offer multiple cooking presets for different foods, allowing staff to switch between settings with small training. Accurate temperature regulation also ensures more uniform cooking across batches, which is especially important during peak service times.

Selecting the right Commercial Deep Fryers capacity depends on volume, menu items, and kitchen layout. Fryers are sized by oil capacity and basket weight limit. High‑volume operations like fast‑casual restaurants may require multiple large fryers to handle peak demand without long wait times. Smaller establishments or those with limited space might choose narrower units or countertop versions.

Capacity planning should also consider future growth and menu expansion. Overloading a fryer can prominent to temperature drop, longer cook times, and inconsistent results. Conversely, oversized fryers in low‑volume kitchens can waste energy and increase costs. Evaluating typical order volume and menu diversity helps determine an effective fryer size.

Oil management is a critical part of operating Commercial Deep Fryers. Oil breaks down over time due to heat and food particles, affecting flavor and potentially producing harmful compounds. Regularly filtering oil removes debris and extends usable life. Scheduling complete oil changes based on usage patterns ensures food quality remains high.

Food safety protocols require kitchens to monitor oil condition and temperature closely. Too much degradation can impact texture, taste, and safety. In addition, proper disposal of used oil must follow local regulations to prevent environmental harm. Many establishments partner with recycling services that convert used cooking oil into biofuel or other products.