- Home

- Product

- About

- Production

- OEM &ODM Solutions

- News

- Contact

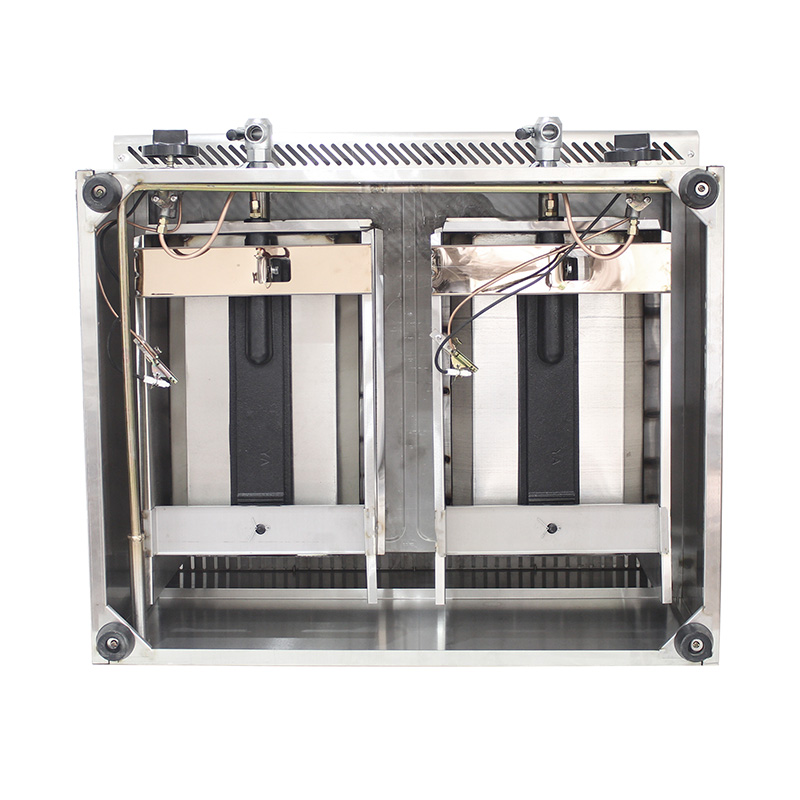

The product is made of 201 stainless steel; the basket is made of nickel-plated iron; and the fuel tank is 0.7 mm thick.

It comes in a cardboard box.

The capacities are 10L single-cylinder and 10L*2 double-cylinder.

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-34

GZL-34

GZL-17

GZL-17

The product is made of 201 grade stainless steel; the basket is nickel-plated iron; and the fuel tank is 0.7 mm thick.

It includes an oil valve, temperature controller, and battery pulse ignition system.

Capacities are available in 10L, 17L, and 25L single-cylinder configurations; and 10L*2, 17L*2, and 25L*2 dual-cylinder configurations. GZL-25 and GZL-50 models do not include a temperature controller. Packaging is in a cardboard box.

The products are made of 201 or 430 stainless steel.

GF90, GF120, and GF150 have CE and ETL certifications, meeting the certification requirements of the European and American markets.

They can use natural gas or liquefied petroleum gas (LPG).

GF90, GF120, and GF150 are equipped with thermostats and temperature limiters to ensure customer safety. GZL-46 and GZL-92 do not include thermostats.

Packaging is in honeycomb cardboard boxes with pallet supports or wooden crates.

For different national requirements, gas valves can be selected according to customer specifications: Robertshaw valve (USA), SIT valve (Italy), and Pucada valve (Taiwan).

Ruian Weixinli Food Machinery Co., Ltd was established in year 1996. The company possesses advanced production equipment, strong technical capabilities, strict quality inspection procedures, and a scientific management system.

Our company always insists on being customer-centric and prioritizing quality belief. We specialize in manufacturing high-quality catering equipment and have developed into an international commercial kitchen equipment manufacturer, with main products including fryers, griddles, pluckers, crepe makers, etc., primarily for export to more than fifty countries and regions, including Germany, Italy, France, Australia, America and Southeast Asia.

Weixinli will continue to work hard, breaking through obstacles in the intense waves of competition, and carefully bringing customers top-quality products with excellent cost performance. We eagerly look forward to joining hands with you to create brilliance together.

Take step and get in touch with us today.

A Standing Stainless Steel Commercial Deep Fryer is a staple in professional kitchens where large-scale frying is required. Its stainless steel construction ensures durability and resistance to corrosion, making it suitable for continuous use in busy environments. Many kitchen operators focus on the fryer’s capacity, as a larger oil volume allows for extended cooking periods without frequent refilling. Additionally, the stainless steel body helps maintain a consistent oil temperature, which is essential for achieving uniform cooking results across different batches of food.

Another key consideration for chefs and restaurant managers is the ease of cleaning. Standing fryers often come with removable baskets, oil drains, and accessible heating elements, allowing staff to maintain hygiene efficiently. In addition, proper maintenance of the stainless steel surface prevents discoloration and extends the lifespan of the fryer, ensuring that the investment remains functional over time.

When using a Gas Fryer, safety is a primary concern in any commercial kitchen. Gas fryers rely on direct flame or gas burners to heat the oil, offering precise temperature control. Users often ask about the importance of monitoring gas pressure and ensuring proper ventilation to prevent fire hazards. Installing a gas fryer in a well-ventilated area reduces the risk of gas leaks and accumulation of fumes, creating a safer workspace for staff.

Temperature control is another critical aspect of operating a gas fryer. Accurate temperature settings prevent food from undercooking or burning while also avoiding excessive oil degradation. Many kitchen professionals emphasize using a thermometer or built-in temperature sensors to maintain oil at the appropriate level. Regular inspection of gas connections and pilot lights ensures the fryer operates efficiently without interruption, which is particularly important during peak service hours.

Commercial Gas Fryers are popular in restaurants and catering services due to their rapid heating capability and energy efficiency. Compared to electric fryers, gas-powered units generally heat oil faster, reducing overall cooking time. This efficiency helps kitchens manage high-volume orders without compromising food quality.

Chefs and kitchen managers often consider the type of gas used—natural gas or propane—as this can influence operating costs and installation requirements. Additionally, modern commercial gas fryers are designed to minimize heat loss and maintain a stable oil temperature, which reduces fuel consumption. Regular maintenance of burners and gas lines also ensures consistent energy performance while preventing unexpected downtime.

Selecting the correct capacity is a frequent question among restaurant owners. A Standing Stainless Steel Commercial Deep Fryer should match the expected volume of fried food in a kitchen. For example, a fryer with two baskets allows multiple items to cook simultaneously, which is useful for fast-food outlets or high-demand settings. Users also consider oil filtration systems that can prolong oil life and maintain food taste.

Cleaning routines are closely tied to fryer capacity. Larger fryers require scheduled oil changes and thorough cleaning to avoid buildup of food residues. Many commercial kitchens implement daily and weekly maintenance schedules to ensure the fryer remains in good condition, which indirectly impacts food quality and operational efficiency.

Operating a Gas Fryer efficiently involves more than turning on the burners. Staff often need guidance on preheating oil to the correct temperature, avoiding overcrowding the baskets, and rotating food items for even frying. Proper oil handling, including skimming and filtering, helps maintain the flavor and reduces waste.

Training kitchen staff to follow safe procedures when using gas fryers is also essential. This includes knowledge of emergency shut-off valves, handling hot oil, and monitoring gas supply. Clear operational protocols reduce the risk of accidents and ensure smooth kitchen workflow during peak hours.

To maximize the lifespan of Commercial Gas Fryers, regular maintenance is key. This includes cleaning the oil reservoir, checking gas connections, and inspecting burners for blockages. Keeping the fryer free of grease and food debris not only improves performance but also prevents unpleasant odors and potential fire risks.

Some commercial kitchens also invest in simple monitoring tools to track gas consumption and fryer usage. By analyzing these metrics, kitchen managers can optimize frying schedules, reduce fuel costs, and plan timely maintenance. Maintaining a consistent cleaning and inspection routine supports both operational efficiency and kitchen safety.