- Home

- Product

- About

- Production

- OEM &ODM Solutions

- News

- Contact

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-10L

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-20

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-25

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-50

GZL-34

GZL-34

GZL-17

GZL-17

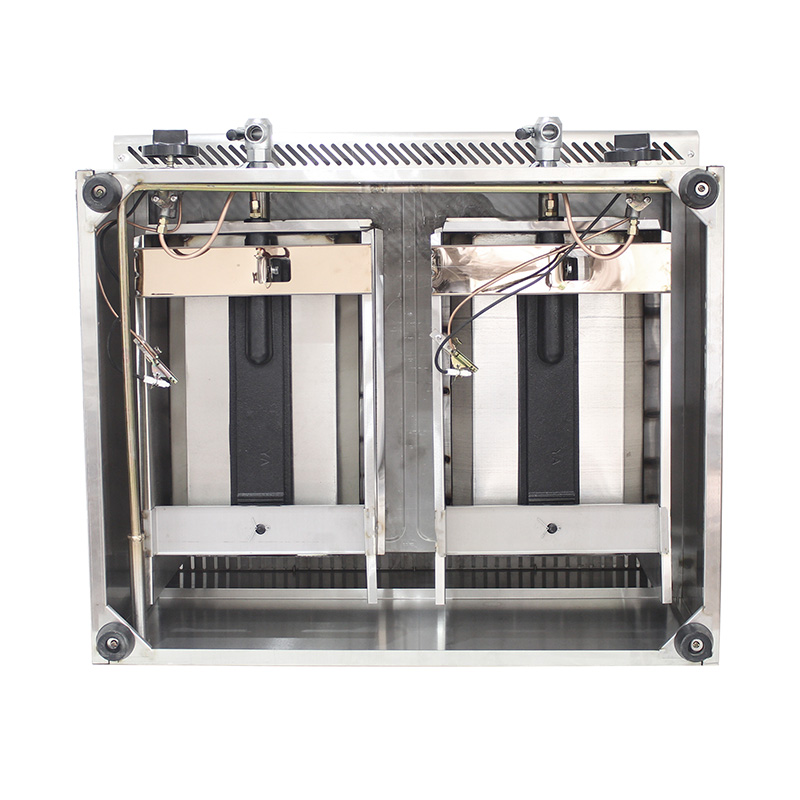

The product is made of 201 grade stainless steel; the basket is nickel-plated iron; and the fuel tank is 0.7 mm thick.

It includes an oil valve, temperature controller, and battery pulse ignition system.

Capacities are available in 10L, 17L, and 25L single-cylinder configurations; and 10L*2, 17L*2, and 25L*2 dual-cylinder configurations. GZL-25 and GZL-50 models do not include a temperature controller. Packaging is in a cardboard box.

The products are made of 201 or 430 stainless steel.

GF90, GF120, and GF150 have CE and ETL certifications, meeting the certification requirements of the European and American markets.

They can use natural gas or liquefied petroleum gas (LPG).

GF90, GF120, and GF150 are equipped with thermostats and temperature limiters to ensure customer safety. GZL-46 and GZL-92 do not include thermostats.

Packaging is in honeycomb cardboard boxes with pallet supports or wooden crates.

For different national requirements, gas valves can be selected according to customer specifications: Robertshaw valve (USA), SIT valve (Italy), and Pucada valve (Taiwan).

Ruian Weixinli Food Machinery Co., Ltd was established in year 1996. The company possesses advanced production equipment, strong technical capabilities, strict quality inspection procedures, and a scientific management system.

Our company always insists on being customer-centric and prioritizing quality belief. We specialize in manufacturing high-quality catering equipment and have developed into an international commercial kitchen equipment manufacturer, with main products including fryers, griddles, pluckers, crepe makers, etc., primarily for export to more than fifty countries and regions, including Germany, Italy, France, Australia, America and Southeast Asia.

Weixinli will continue to work hard, breaking through obstacles in the intense waves of competition, and carefully bringing customers top-quality products with excellent cost performance. We eagerly look forward to joining hands with you to create brilliance together.

Take step and get in touch with us today.

A Fryer is one of the more widely used pieces of thermal cooking equipment in commercial kitchens. From an industry perspective, a fryer operates by heating cooking oil to a controlled temperature, allowing food to cook rapidly through full oil immersion or surface contact, depending on design.

One major concern associated with a fryer is temperature stability. Uneven heat distribution can affect food texture and color, especially during continuous operation in busy kitchens. Modern fryer designs focus on accurate thermoreats, fast heat recovery, and consistent oil circulation to reduce cooking fluctuations. Another frequently discussed topic is oil degradation, as repeated heating causes oxidation and residue buildup. This directly influences food taste, appearance, and operating costs.

Safety is another common point of attention. Commercial fryer users often look for information on overheating protection, splash prevention, and oil drainage design. In response to these concerns, industrial fryers typically integrate insulated housings, safety limit switches, and controlled oil outlets to reduce operational risk. From an industry knowledge standpoint, selecting a fryer is not only about capacity, but also about how well it balances heat control, oil life, and operator safety.

The term Deep Fryer is closely associated with professional foodservice environments where consistent output and high production volume are required.

A deep fryer is designed to fully submerge food in hot oil, which places higher demands on oil quality management. One of the more discussed industry topics is oil filtration and replacement cycles. Poor oil management can result in uneven frying, excessive smoke, and increased waste. From a technical perspective, deeper oil tanks allow better heat distribution, but they also require proper filtration systems to remove food particles and maintain stable performance.

Capacity selection is another area users frequently research. Deep fryers are available in single-tank and multi-tank configurations, and capacity should match menu volume rather than floor space alone. Overloading a deep fryer can reduce oil temperature rapidly, pilot to inconsistent results and longer cooking times. Industry professionals often emphasize matching fryer capacity with peak service demand to maintain efficiency.

Energy use is also a key concern. Whether powered by electricity or gas, a deep fryer must balance heating speed with steady temperature maintenance. Improved insulation, efficient heating elements, and responsive control systems are widely discussed solutions within the industry. These features help reduce standby energy loss while supporting continuous frying during busy service periods.

Restaurant Fryers are specifically designed to meet the demands of commercial foodservice operations, including quick-service restaurants, hotels, and catering kitchens.

Menu versatility is a major factor influencing fryer selection. Restaurant fryers must handle a wide range of food items, from frozen products to fresh ingredients, without flavor transfer. This has led to increased interest in independent temperature controls, multiple baskets, and zone-based heating designs. These features help restaurants manage different products while maintaining consistent output.

Cleaning and maintenance are also high-priority concerns. In commercial environments, downtime directly affects service efficiency. As a result, restaurant fryers are often evaluated based on oil drainage design, smooth interior surfaces, and accessibility of heating components. Easy-to-clean structures reduce labor time and support daily hygiene routines, which is an important topic frequently discussed in online searches.

Compliance with food safety and electrical or gas standards is another widely searched topic related to restaurant fryers. Commercial kitchens must follow strict regulations regarding materials, temperature control, and operational safety. From an industry knowledge standpoint, restaurant fryers are typically designed with food-grade stainless steel, sealed control panels, and reliable temperature limit systems to meet inspection requirements in different regions.

Across Fryer, Deep Fryer, and Restaurant Fryers categories, industry trends show a growing focus on efficiency, durability, and adaptability. This has driven attention toward modular designs, improved thermal efficiency, and standardized components that simplify maintenance.

Another important trend is export-oriented compliance. As restaurant equipment is used globally, commercial fryers must adapt to different voltage systems, fuel types, and safety regulations. This makes design flexibility and technical documentation important considerations for international buyers.

From an SEO and industry content perspective, addressing these practical concerns helps align website pages with real user intent. By focusing on how fryers function, how deep fryers manage oil and energy, and how restaurant fryers support daily commercial operations, websites can provide valuable, search-relevant information that supports both visibility and credibility.