- Home

- Product

- About

- Production

- OEM &ODM Solutions

- News

- Contact

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810

CHZ-810A

CHZ-810A

CHZ-810A

CHZ-810A

CHZ-810A

CHZ-810A

CHZ-810B

CHZ-810B

CHZ-810B

CHZ-810B

CHZ-810B

CHZ-810B

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820A

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

CHZ-820B

The machine body is made of 201 stainless steel, and the grill plates are coated with Teflon. To meet customer needs, the equipment is available in different sizes and grill plate types.

The single-plate grill offers three grill plate types: A is semi-flat (bottom plate flat, top plate groove), B is fully flat, and the rest are fully grooved.

It has CE and RoHS certifications, meeting the certification requirements of the European market.

It meets different voltage and frequency requirements: 220~240V/50~60Hz; 110V/60Hz.

Carton packaging.

The machine body is made of 201 stainless steel, and the grill plates are coated with Teflon. To meet customer needs, the equipment is available in different sizes and grill plate types.

The double-plate grill offers three grill plate types: A is semi-flat (bottom plate flat, top plate groove), B is fully flat, and the rest are fully grooved.

It has CE and RoHS certifications, meeting the certification requirements of the European market.

It meets different voltage and frequency requirements: 220~240V/50~60Hz; 110V/60Hz.

Carton packaging.

The unit body is made of 201 stainless steel and features European-style automatic ignition. Power is 20.6kW. Volcanic rock is not included and must be purchased separately by the customer. It can use natural gas or liquefied petroleum gas.

Wooden crate packaging.

The unit is constructed of 430 or 201 stainless steel, with a 3/4-inch gas inlet for American-style operation and manual ignition. Burners are available in 1, 2, 3, or 4 units.

Volcanic rock is not included and must be purchased separately. It can use natural gas or LPG. It is packaged in a wooden crate.

The product is made of 201 stainless steel, making it durable and rust-resistant. The machine features top heating, with meat juices flowing down the slope into the bottom oil collection tank. Customers can manually control the position of the steak and the top heating element by adjusting the side handle. The top temperature quickly caramelizes the surface of the steak while retaining maximum juices. Manual flipping is required.

Meets different voltage and frequency requirements: 220~240V/50~60Hz; 110V/60Hz.

Carton packaging.

The product is made of stainless steel, making it durable and rust-resistant.

The electric grill meets various voltage and frequency requirements: 220~240V/50~60Hz; 110V/60Hz.

Available in different sizes, suitable for small to medium-sized commercial vendors.

Wooden crate packaging.

The product is made of stainless steel, making it durable and rust-resistant.

The gas grill can use natural gas or liquefied petroleum gas.

Available in various sizes, suitable for small to medium-sized commercial vendors.

Wooden crate packaging.

CHZ-N80

CHZ-N80

CHZ-N50-1

CHZ-N50-1

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

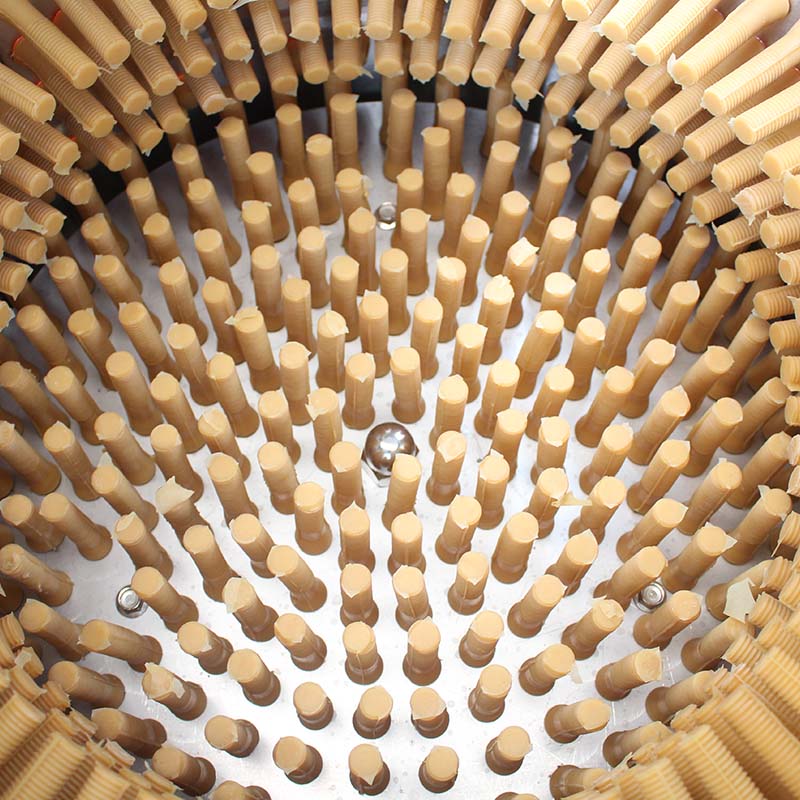

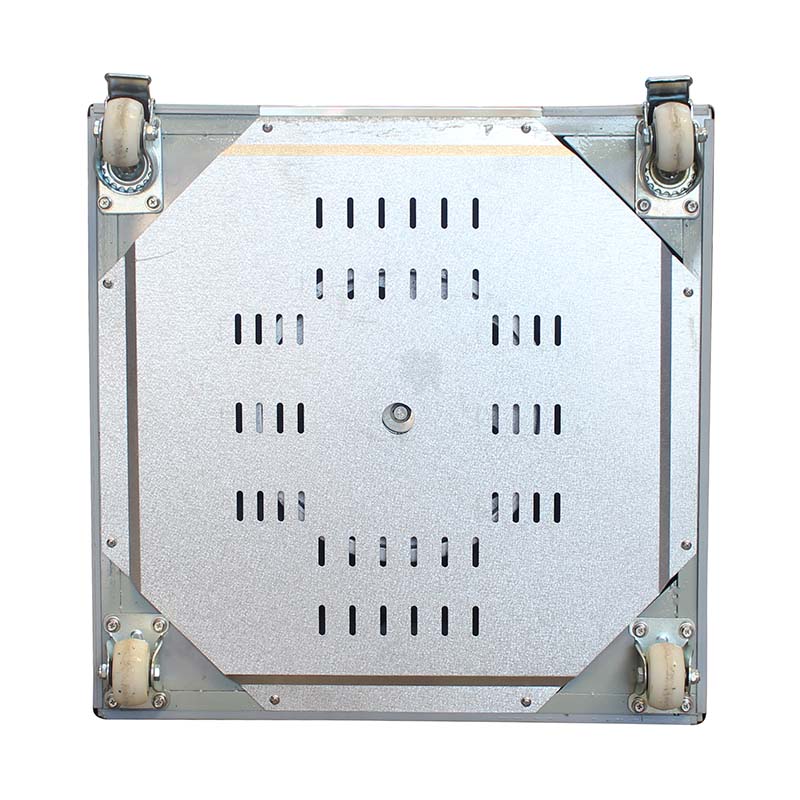

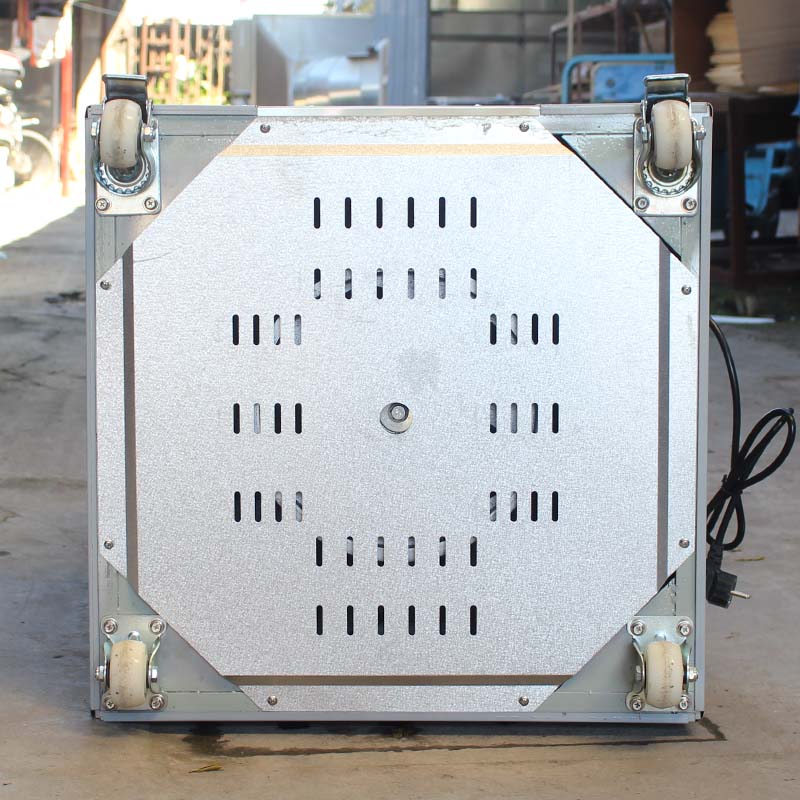

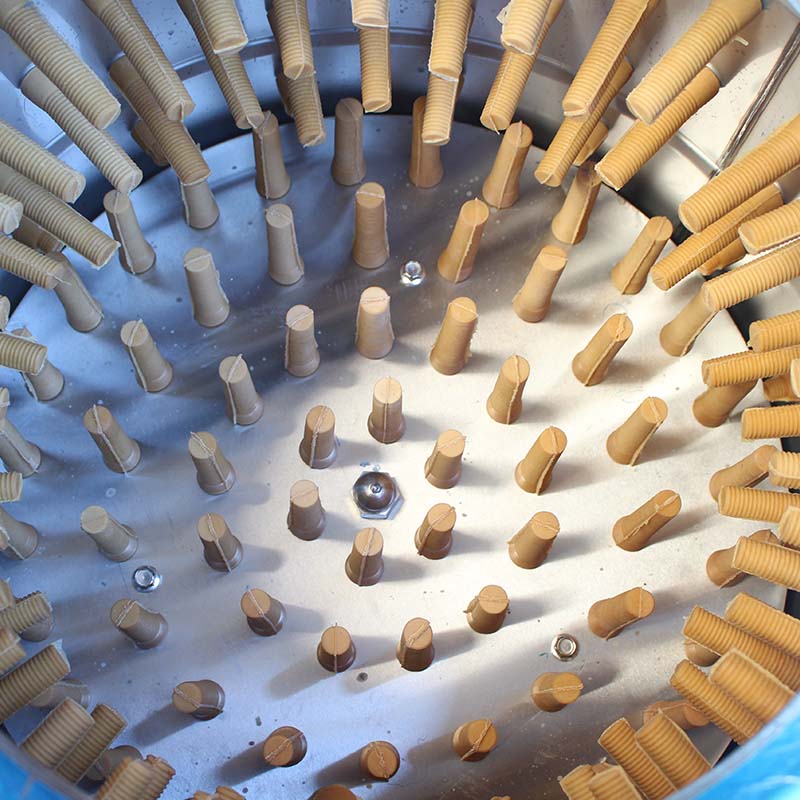

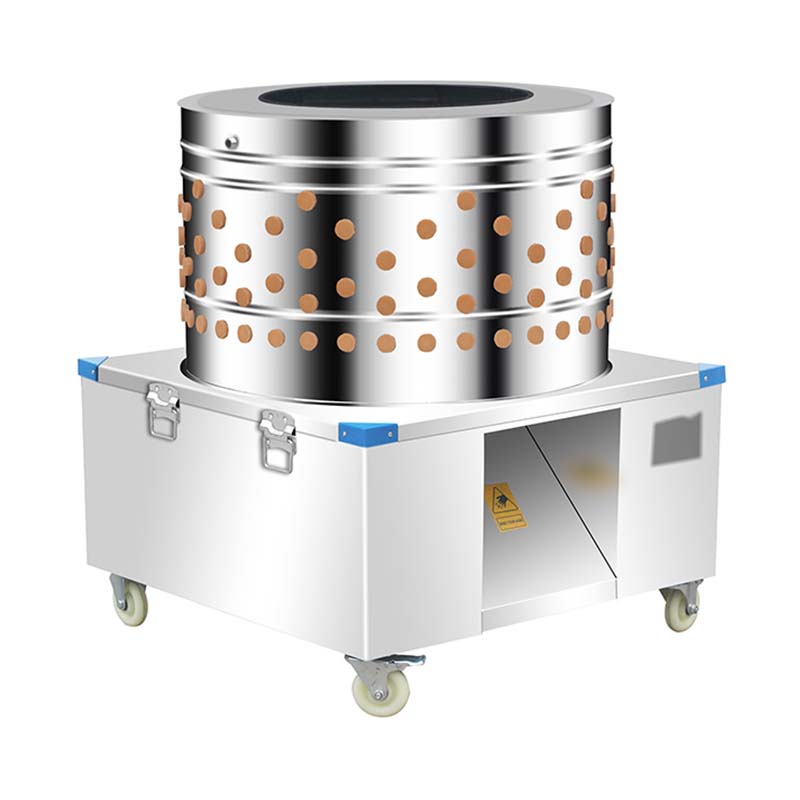

The product body is made of 201 stainless steel, and the lid is made of 430 stainless steel. It includes a plucker rubber stick. Durable and rust-resistant.

All plucker machines are CE and RoHS certified, meeting European market certification requirements.

Different voltage and frequency requirements are met depending on the customer's country, and copper or aluminum motors are available for different voltages. Options: 220~240V/50~60Hz; 110V/60Hz.

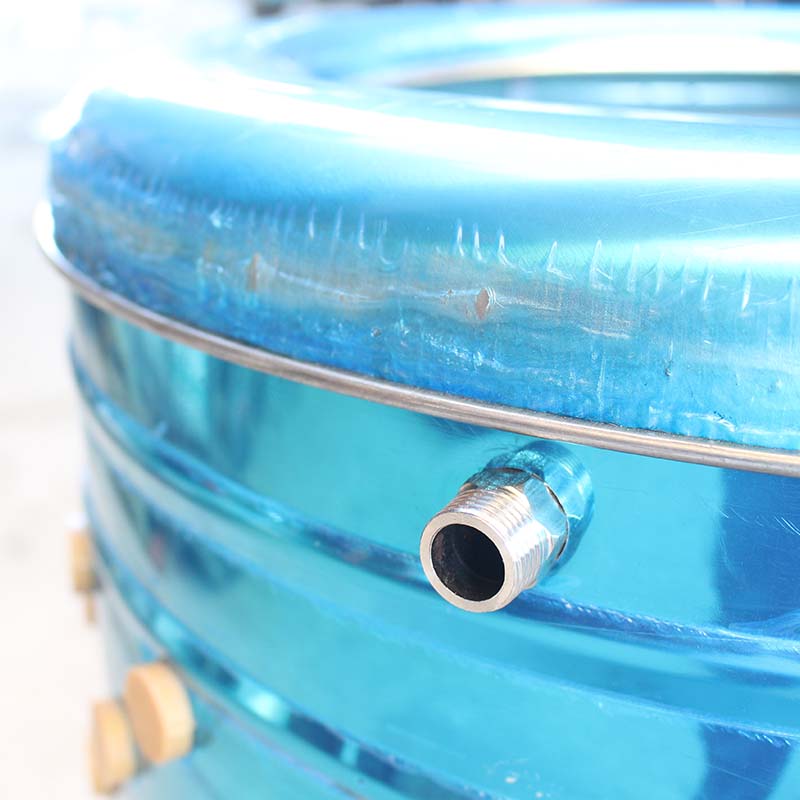

The N series is the newer model, offering a choice of wheels, hoses, posts, and other accessories. It also features more rubber stick fingers and a waterproof motor. Older models did not have these features.

Wooden crates are used for packaging; smaller items can also be packaged in honeycomb cardboard boxes.

The product is made of 201 stainless steel, making it durable and rust-resistant.

All heat exchangers are CE, RoHS certified, meeting European market certification requirements.

Voltage and frequency requirements vary depending on the customer's country of origin, with options available: 220~240V/50~60Hz; 110V/60Hz.

The heat exchangers are equipped with thermostats and temperature limiters to ensure customer safety. Honeycomb cardboard packaging.

The product is made of 201 stainless steel and includes a depilatory rubber rod. It is durable and rust-resistant.

All heat exchangers are CE, RoHS certified, meeting European market certification requirements.

Different voltage and frequency requirements are available depending on the customer's country, with copper and aluminum motors available for different voltages. Options: 220~240V/50~60Hz; 110V/60Hz.

A temperature limiter is included to ensure customer safety. Wooden crate packaging.

Made of 201 stainless steel, available in various sizes for slaughtering chickens, categorized according to the size of poultry to be plucked. The KC-4 can also be used in combination to slaughter multiple types of poultry simultaneously, aiding in bleeding and ensuring thorough blood removal.

Packaged in a honeycomb cardboard box.

Stainless Steel Combination Chicken Killing Cones are designed to streamline poultry processing with a clean, humane, and efficient workflow.

Made from durable stainless steel, these cones are available in multiple sizes to accommodate different poultry weights and species.

By combining several cones into a single KC-4 setup, the system enables multi-bird processing at the same time, improving efficiency while ensuring proper bleeding for higher meat quality.

The sturdy construction maintains shape during use, and each cone supports secure positioning to reduce wing flapping and bruising.

Products are packed in protective honeycomb cartons for safe transport and storage.

Ruian Weixinli Food Machinery Co., Ltd was established in year 1996. The company possesses advanced production equipment, strong technical capabilities, strict quality inspection procedures, and a scientific management system.

Our company always insists on being customer-centric and prioritizing quality belief. We specialize in manufacturing high-quality catering equipment and have developed into an international commercial kitchen equipment manufacturer, with main products including fryers, griddles, pluckers, crepe makers, etc., primarily for export to more than fifty countries and regions, including Germany, Italy, France, Australia, America and Southeast Asia.

Weixinli will continue to work hard, breaking through obstacles in the intense waves of competition, and carefully bringing customers top-quality products with excellent cost performance. We eagerly look forward to joining hands with you to create brilliance together.

Take step and get in touch with us today.

Food heater machine systems play a critical role in modern gas catering equipment and fast food kitchen equipment. Many users focus on how heating equipment supports food temperature control, workflow efficiency, and food safety in commercial kitchens. In fast-paced foodservice environments, heater machines are not only used for warming but also for holding, pre-cooking, and stabilizing food temperatures during peak service periods. Gas-powered catering setups often integrate food heater machines to ensure consistent heat distribution while reducing dependence on electrical loads.

Search trends show that buyers are increasingly concerned with structure, material, and heating methods when selecting a food heater machine for gas catering equipment and fast food kitchen equipment. Stainless steel construction is often discussed due to hygiene and durability requirements. Users also pay attention to whether the heater machine supports modular installation, allowing it to be paired with fryers, griddles, or pancake machines. In fast food kitchens, compact footprints and front-access maintenance designs are frequently mentioned, as space efficiency and ease of cleaning affect daily operations.

Food heater machine configurations in gas catering equipment are often evaluated based on gas consumption, thermal insulation, and heat retention performance. For fast food kitchen equipment, stable heat output is important to avoid frequent reheating cycles that increase fuel use. Many operators search for heater machines that balance heating speed with controlled energy output, helping reduce operational costs while maintaining steady kitchen workflows during long service hours.

Food safety remains a major concern in online discussions related to food heater machine applications. Gas catering equipment must comply with food contact and temperature-holding standards to reduce contamination risks. In fast food kitchen equipment setups, heater machines are often used to maintain cooked food at safe serving temperatures without overcooking. Users commonly research how evenly heat is distributed, whether thermoreats are adjustable, and how temperature stability is maintained during continuous operation.

A food heater machine used in gas catering equipment is expected to withstand grease, steam, and frequent cleaning cycles. Fast food kitchen equipment operators often look for heater machines with removable trays, smooth internal surfaces, and accessible burners or heating elements. Reduced downtime for cleaning and servicing is a key factor influencing purchasing decisions, especially in high-volume foodservice environments.

Users often search for practical application scenarios before purchasing. Food heater machine units are widely used alongside fryers, flat griddles, and crepe or pancake machines in gas catering equipment lines. In fast food kitchen equipment layouts, heater machines may function as holding stations for fried foods, warming units for prepared ingredients, or temperature stabilizers before final assembly. This flexibility is frequently discussed in buyer guides and industry articles, reflecting the demand for multi-purpose kitchen solutions.

Compliance and Market Expectations for Food Heater Machine in Gas Catering Equipment and Fast Food Kitchen Equipment

Another area of interest is compliance and export suitability. Food heater machine products integrated into gas catering equipment and fast food kitchen equipment are expected to meet different market requirements, including safety standards, material regulations, and operational reliability. Buyers exporting to multiple regions often research whether heater machines are adaptable to different gas types and kitchen regulations, as this affects long-term usability across international markets.

Finally, industry discussions point toward future development trends. Food heater machine designs for gas catering equipment are gradually focusing on improved thermal control and user-friendly operation. In fast food kitchen equipment, there is a growing interest in heater machines that support automation, standardized cooking processes, and consistent output quality. These trends reflect changing expectations in commercial kitchens, where efficiency, safety, and adaptability continue to shape purchasing decisions.