- Home

- Product

- About

- Production

- OEM &ODM Solutions

- News

- Contact

CHZ-N80

CHZ-N80

CHZ-N50-1

CHZ-N50-1

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N30

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N40

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N50

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N55

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N60

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

CHZ-N80

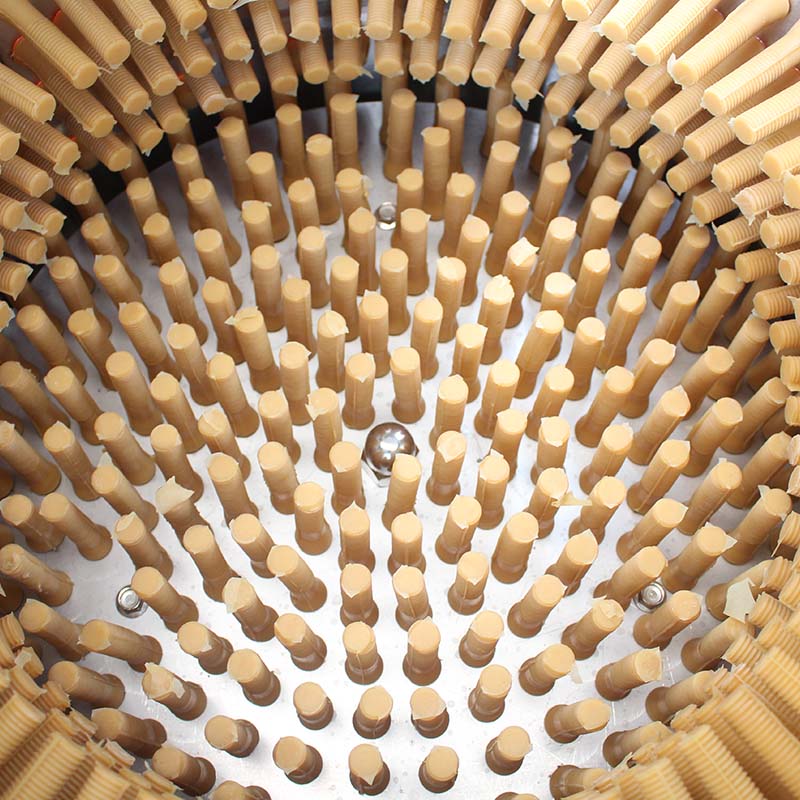

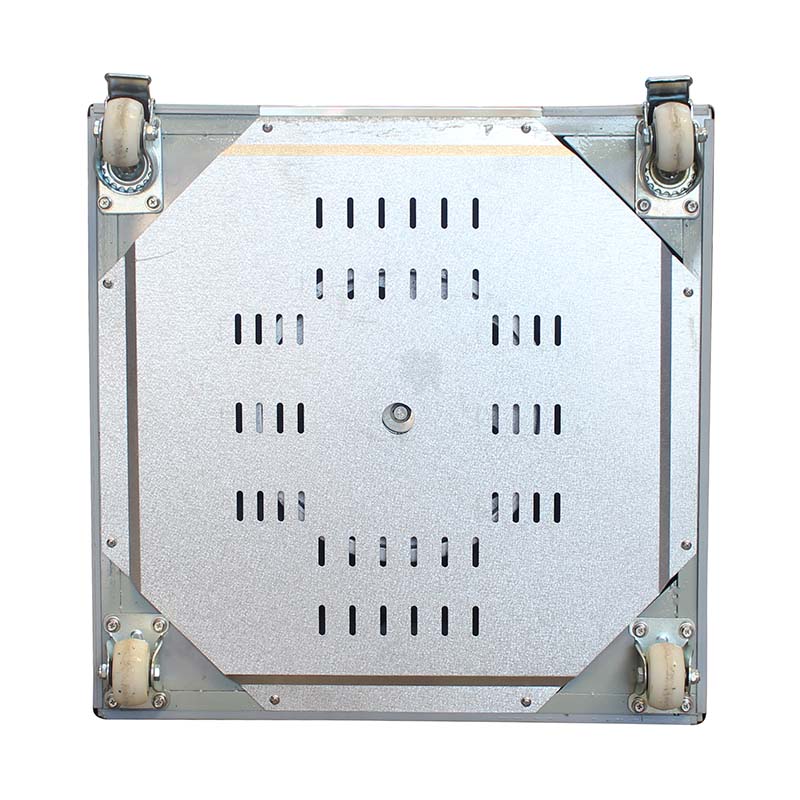

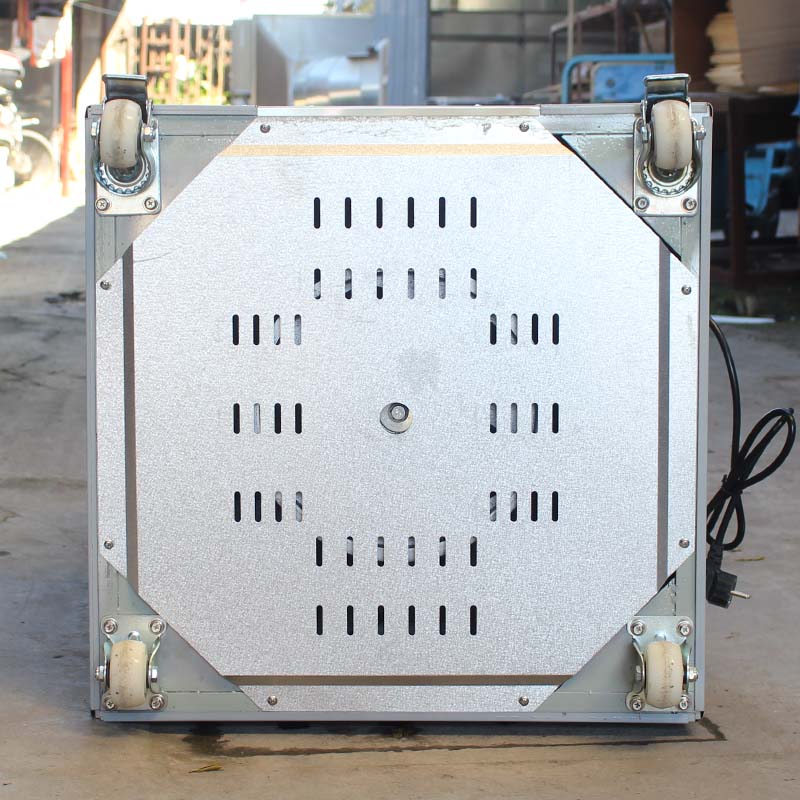

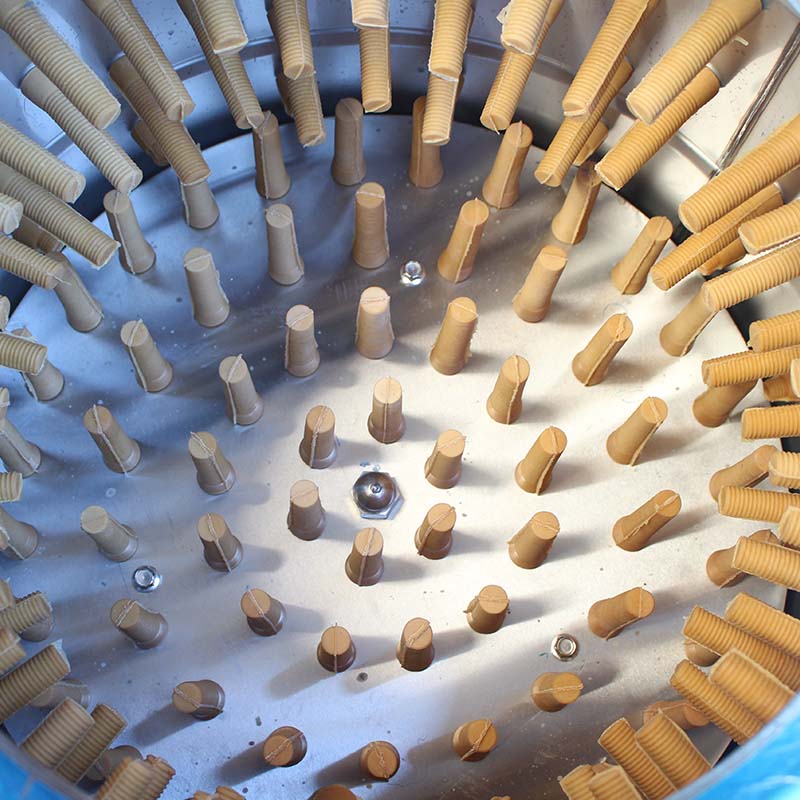

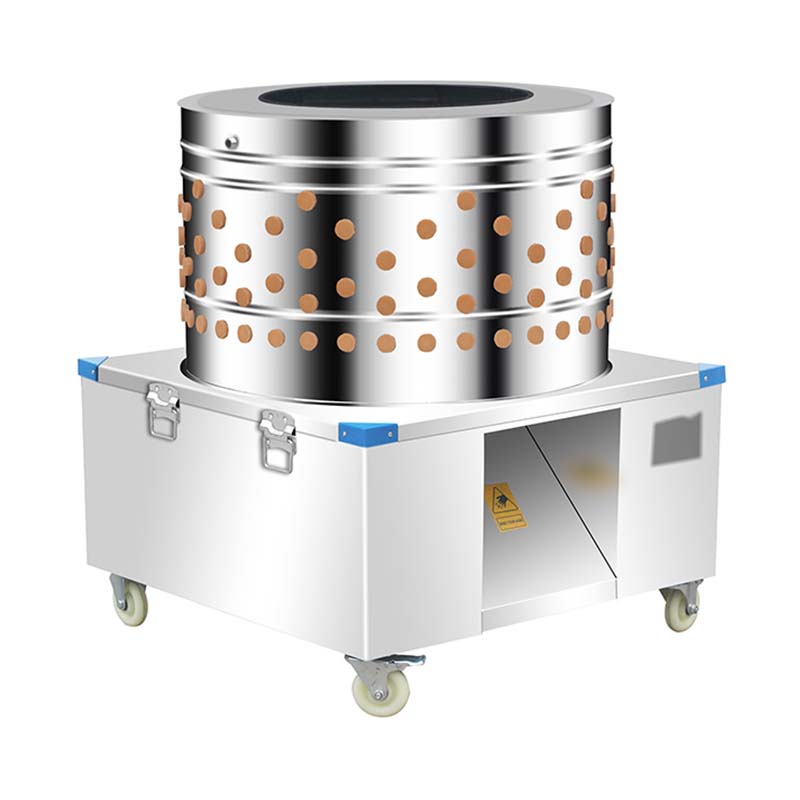

The product body is made of 201 stainless steel, and the lid is made of 430 stainless steel. It includes a plucker rubber stick. Durable and rust-resistant.

All plucker machines are CE and RoHS certified, meeting European market certification requirements.

Different voltage and frequency requirements are met depending on the customer's country, and copper or aluminum motors are available for different voltages. Options: 220~240V/50~60Hz; 110V/60Hz.

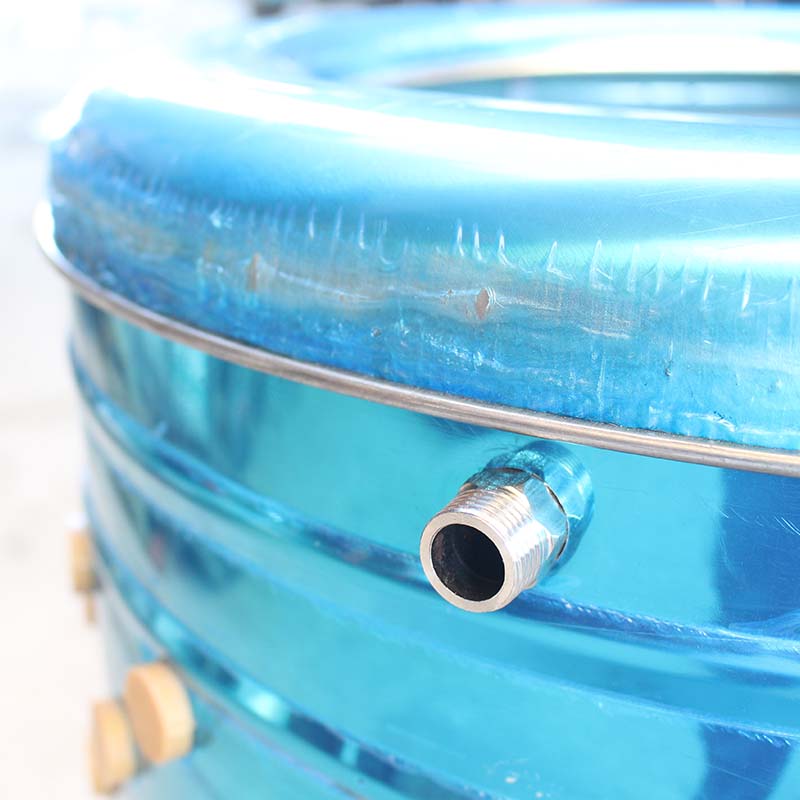

The N series is the newer model, offering a choice of wheels, hoses, posts, and other accessories. It also features more rubber stick fingers and a waterproof motor. Older models did not have these features.

Wooden crates are used for packaging; smaller items can also be packaged in honeycomb cardboard boxes.

The product is made of 201 stainless steel, making it durable and rust-resistant.

All heat exchangers are CE, RoHS certified, meeting European market certification requirements.

Voltage and frequency requirements vary depending on the customer's country of origin, with options available: 220~240V/50~60Hz; 110V/60Hz.

The heat exchangers are equipped with thermostats and temperature limiters to ensure customer safety. Honeycomb cardboard packaging.

The product is made of 201 stainless steel and includes a depilatory rubber rod. It is durable and rust-resistant.

All heat exchangers are CE, RoHS certified, meeting European market certification requirements.

Different voltage and frequency requirements are available depending on the customer's country, with copper and aluminum motors available for different voltages. Options: 220~240V/50~60Hz; 110V/60Hz.

A temperature limiter is included to ensure customer safety. Wooden crate packaging.

Made of 201 stainless steel, available in various sizes for slaughtering chickens, categorized according to the size of poultry to be plucked. The KC-4 can also be used in combination to slaughter multiple types of poultry simultaneously, aiding in bleeding and ensuring thorough blood removal.

Packaged in a honeycomb cardboard box.

Stainless Steel Combination Chicken Killing Cones are designed to streamline poultry processing with a clean, humane, and efficient workflow.

Made from durable stainless steel, these cones are available in multiple sizes to accommodate different poultry weights and species.

By combining several cones into a single KC-4 setup, the system enables multi-bird processing at the same time, improving efficiency while ensuring proper bleeding for higher meat quality.

The sturdy construction maintains shape during use, and each cone supports secure positioning to reduce wing flapping and bruising.

Products are packed in protective honeycomb cartons for safe transport and storage.

Made of 201 stainless steel, it features a depilatory rubber stick for even and uniform depilation with minimal damage to chicken, duck, and goose carcasses, making it suitable for applications where high quality and appearance of the meat are important.

Ruian Weixinli Food Machinery Co., Ltd was established in year 1996. The company possesses advanced production equipment, strong technical capabilities, strict quality inspection procedures, and a scientific management system.

Our company always insists on being customer-centric and prioritizing quality belief. We specialize in manufacturing high-quality catering equipment and have developed into an international commercial kitchen equipment manufacturer, with main products including fryers, griddles, pluckers, crepe makers, etc., primarily for export to more than fifty countries and regions, including Germany, Italy, France, Australia, America and Southeast Asia.

Weixinli will continue to work hard, breaking through obstacles in the intense waves of competition, and carefully bringing customers top-quality products with excellent cost performance. We eagerly look forward to joining hands with you to create brilliance together.

Take step and get in touch with us today.

Poultry Killing Equipment is a critical component in modern poultry processing facilities, especially as global markets place increasing attention on food safety, animal welfare, and operational efficiency. Equipment design must support humane stunning and killing methods, ensuring birds are handled with controlled parameters such as voltage, timing, and positioning to reduce stress and physical damage.

Another widely discussed aspect of Poultry Killing Equipment is hygiene and contamination control. Buyers frequently look for equipment constructed with food-grade stainless steel, smooth welding seams, and designs that result in less residue buildup. Easy disassembly and wash-down capability are often highlighted as essential features, as they directly affect daily sanitation procedures and long-term compliance with food safety regulations.

Energy consumption and production capacity are also common decision factors. Poultry processors want equipment that balances throughput with stable energy use, particularly in regions where electricity costs or regulatory requirements affect operating expenses. Adjustable settings that allow the same Poultry Killing Equipment to process different bird sizes can help facilities adapt to market demand without frequent equipment replacement.

A Poultry Killing Equipment system refers to the integrated setup that connects killing, bleeding, scalding, plucking, and downstream processing steps into a coordinated workflow. One major topic of users' research is how well a Poultry Killing Equipment system integrates with existing processing lines. Compatibility with conveyors, hanging lines, and control systems is essential for reducing installation complexity and production downtime.

Automation is another area of strong interest. Modern poultry plants increasingly rely on automated Poultry Killing Equipment systems to ensure consistent processing results while reducing manual intervention. Automated control panels, programmable logic controllers, and sensor-based monitoring help operators maintain stable parameters throughout the killing process. This level of control supports traceability and documentation, which are often required for export-oriented poultry processors.

Compliance with regional and international regulations is also a key concern. A Poultry Killing Equipment system must support operational practices aligned with food safety authorities and animal welfare guidelines. Users often look for systems that allow clear documentation of processing conditions, such as stunning duration and electrical settings, as these records are important during audits and inspections. Additionally, modular system designs are frequently favored, as they allow processors to upgrade individual components without replacing the entire line.

An Electric Chicken Plucker for Poultry Processing plays a significant role in determining final carcass appearance and processing efficiency. Properly designed plucking machines use controlled rotation speeds and flexible plucking fingers to remove feathers while reducing skin tearing and bruising.

Material selection is another commonly discussed factor. An Electric Chicken Plucker for Poultry Processing is typically exposed to moisture, feathers, and organic residue throughout daily operations. As a result, corrosion resistance, water sealing, and ease of cleaning are important considerations for buyers. Equipment designs that support quick maintenance and finger replacement can reduce downtime and improve long-term usability.

Processing capacity and adaptability are also frequently mentioned in user queries. Poultry processors often handle different bird weights within the same facility, so an Electric Chicken Plucker for Poultry Processing must be capable of adjusting to varying sizes without extensive mechanical changes. Noise control and vibration stability are additional aspects gaining attention, particularly for facilities seeking improved working conditions and compliance with local workplace regulations.

From a production standpoint, reliable plucking performance directly affects downstream processes such as evisceration and chilling. Clean feather removal helps maintain a consistent processing flow and reduces the need for manual rework, which can increase labor costs. For this reason, Electric Chicken Plucker for Poultry Processing equipment is often evaluated not only as a standalone machine, but as a key contributor to overall line efficiency.